About centrifugation

About centrifugation

Centrifugation is a technique that uses g-force to separate different types of mixtures. The centrifuge is a device that usually has a rotor, which rotates around a fixed axis.

042-300 91 30

Do you have any questions? Call customer service

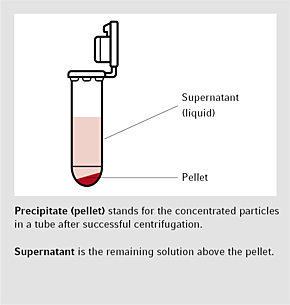

The centrifuge works on the principle of sedimentation. Under the influence of the g-force, the sample is separated, depending on the density of the constituents. There are several types of known separation processes. To name a few, there is ultrafiltration, phase separation and pelleting (see Figure 1)

Figure 1 Formation of pellets after centrifugation

Pelleting is the most common application. In this form of centrifugation, the particles form a pellet at the bottom of your centrifuge tube and the liquid that remains is called supernatant. During the separation phase, the chemicals are converted from a matrix/aqueous media into a solution. During ultrafiltration, macromolecules are purified and separated using a filter. separated. Isopycnic centrifugation works by forming a gradation of density through equilibrium sedimentation. Centrifugation protocols usually take into account rcf (relative centrifugal force) and the degree of acceleration in multiples of g (g-force). Using rpm (revolutions per minutes) is very imprecise.

Key definitions

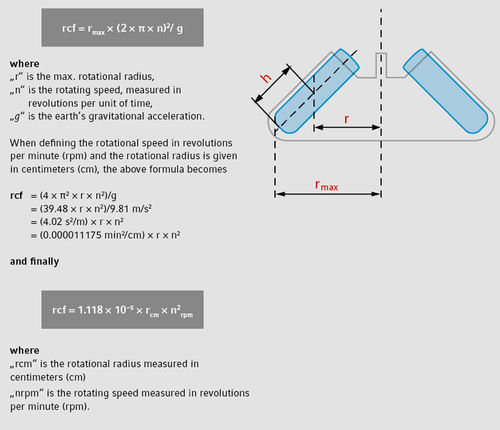

2). The difference between rpm and rcf is significant, as two rotors with different diameters, but at the same rpm, will give rise to two different rcf.

Figure 2 Calculation of rcf

What is the reason for this?

Since the motion of the rotor is circular, the acceleration force (× g) is calculated as a product of the radius and the square of the velocity angle. The result of this equation is what has historically been called rcf “relative centrifugal force”.

Example (calculation according to Figure 2)

| Rotor A | Rotor B | |

|---|---|---|

| Speed | 14,000 rpm | 14,000 rpm |

| Radius | 5.98 cm | 9.50 cm |

| Gravity | 13,100 × g | 20,817 × g |

Both centrifuges can centrifuge with one rotor, with tubes containing 1.5/ 2 mL, at the same speed (14,000 rpm), but the acceleration is different 13,100 × g versus 20,817 × g. This gives rise to different results. To make things easier, many centrifuges have a button that can directly convert rpm to rcf and vice versa. If your centrifuge does not have this automatic button, it can be calculated using the formula above. The K-factor is a parameter for the distance of sedimentation in a tube. This factor is also called the clean-up factor and represents the relative efficiency of pellet formation at maximum rotation speed, for a centrifuge system. Usually the k-factor is used as a value to estimate the time (in hours) for a certain sample, with a certain sedimentation coefficient, to settle. The sedimentation coefficient is measured in S (Svedberg).

A small k-factor, represents a faster separation. The value of the k-factor is primarily defined by the rotor diameter. Compared to rpm/rcf, the k-factor has become less important in today’s centrifugation processes. However, for ultracentrifugation, the k-factor is still of very high value.

Different types of centrifuge models

There are two types of centrifuges, floor models or bench models.

Floor models can usually spin at very high g-numbers and have a large capacity. However, these centrifuges take up quite a large floor space. These centrifuges are used, for example, in ultracentrifugation.

As for the countertop centrifuges, these come in two variants, microcentrifuges or multifunction centrifuges. Microcentrifuges are mostly used for small volume tubes (microtiter tubes). These centrifuges are small, agile, but have a limited capacity and possible g-force. As for multifunction centrifuges, they have a wider range of applications and depending on the rotor and adapters you use, you can centrifuge everything from tubes to plates.

Choosing the right centrifuge for the job

If you follow a given protocol, make sure you use the same rotor, the same speed, the same temperature and the same spin time. If you want the most optimal spinning possible, keep these parameters in mind:

- Type of sample

- In what is the sample (tube, plate etc)

- Type of centrifuge (regular, cooling or heating)

- Type of rotor (swingout bucket or fixed angle)

- Desired g-number (RCF), RPM = speed is calculated based on the desired RCF (g-number) and the radius to the correct point in the sample on the rotor you use, which is done automatically on many centrifuges. If you are unsure, ask us and we will help you.

- How many minutes the sample should be centrifuged

- What temperature is desirable during the spinning (is cold or heat needed)

What type of rotor should I choose?

The two most common rotors are fixed-angle or swing-bucket. However, there are other variants of rotors, such as drum rotors, and constant flow rotors.

Fixed angle rotor

The obvious advantage is that the rotor has no moving parts. As a result, the metal of the rotor is not subjected to as much wear, higher g-forces can be achieved and thus the required spin time is reduced. The only drawback is that this rotor has limited capacity. The position of the pellets formed depends very much on the inclination of the tube. Most often the slope is 45°. The greater the slope of the pipe, the tighter the pellets will be. Small rotors give rise to pellets, which then have a larger spreading surface.

Swing bucket rotors

These rotors are more flexible and depending on the inserts you use, you can spin anything from tubes to plates. The moving parts of this rotor mean that there is more wear and tear, compared to a fixed angle rotor. Because of the higher wear, you can’t use as high g-forces and the spinning takes longer. Based on the swing-bucket principle, the pellets end up at the bottom of the tube.

Things to consider when using your centrifuge

What causes imbalances?

The rotors spin at a tremendous speed and cause extreme forces. With this in mind, it is very important to balance the samples when running. This is especially important when the centrifuge is not completely full of samples, then you really have to think about how the samples are placed, to achieve balance.

What are the risks when an imbalance occurs?

If you place your samples incorrectly and cause an imbalance, this can cause damage to the rotor. The imbalance can also cause strong vibrations, which can damage the entire centrifuge. In the worst case, very large imbalances can lead to the destruction of the entire rotor and centrifuge. Most of our centrifuges have an imbalance switch that breaks as soon as it detects too much imbalance, however, it is still very important to always balance your samples correctly when running a centrifuge, this also increases the life of the centrifuge.

Does the centrifuge understand that there is an imbalance?

Many centrifuges have a built-in imbalance control (via built-in sensors), which causes the centrifuge to slow down or completely shut down if an imbalance occurs. Note that smaller models of centrifuges, which do not reach high speeds, usually do not have built-in sensors. On these centrifuges, you will notice the imbalance through increased vibrations, when spinning.

What to do when an imbalance occurs?

If the centrifuge starts to vibrate intensely, turn it off immediately, there is an imbalance. Small vibrations are normal when centrifuging, while strong vibrations can cause damage/serious damage. Once you have stopped your centrifuge, see if the samples were unbalanced. If problems occur during centrifugation, even though your samples are balanced, contact the LabTeam immediately, and we will come out to you and help you and perform service and control.

How do I load the samples correctly?

How to avoid imbalances?

- Make sure that the working surface of the centrifuge is flat

- At high speeds, imbalances can easily occur if the volumes of the samples do not match:

- For fixed-angle rotors, it is important to balance the samples in terms of weight. Make sure it is the same tube and the same weight on the opposite samples

- For swing-out rotors, it is important to have containers in all positions. Each container has a maximum weight, which must not be exceeded. Make sure to balance your samples well with similar volumes.

Loading of samples

- Make sure that the rotor is adapted to the tubes you want to centrifuge. It’s a good idea to use adapters so that your samples are stable during centrifugation. If you use a swing-out rotor, make sure that the tubes are not too long so they hit when the beaker swings out. If you use aerosol-tight caps, make sure the tubes are not too long and the cap closes properly.

- Inspect the container for your samples, so there are no cracks. At high speeds, samples in liquid form can turn into aerosols, unless the container for the sample is complete.

Charging a swing-out rotor

- If you use your swing-out rotor and it is not full, make sure to balance, as shown above

- Make sure that all samples are correctly labeled, to keep track even after centrifugation

- You can wipe the outside of the samples with disinfectant, to avoid the spread of aerosols (formed at high speeds)

- Make sure you have not overfilled the container for your sample

- Never load samples while they are in the centrifuge. Always load the samples beforehand.

Charging a fixed angle rotor

- If you are using your fixed angle rotor and it is not full, make sure to balance, as shown above

- Make sure that all samples are correctly labeled, to keep track even after centrifugation

- Wipe the outside of the samples with disinfectant, to avoid the spread of aerosols (formed at high speeds)

- Make sure you have not overfilled the container for your sample

- Never load samples while they are in the centrifuge. Always load the samples beforehand.

Automatic recognition of the rotor

Many centrifuges, especially bench top models that can be used in multiple ways, have automatic rotor recognition. You choose which RCF (g-number) you want to run and the function detects the newly inserted rotor, based on the rotor it has detected, it automatically calculates the correct rpm based on the RCF (G-number) you have chosen to run on. On the smaller centrifuge models, this feature is not available, but all rotors are adapted to be able to rotate according to the centrifuge model’s given maximum speeds.

This is a small guide and not a complete instruction, we always refer to the manual of each equipment for complete info that applies to each equipment and model.